In this guide, we will explore the key differences between insert molding and overmolding processes in manufacturing. Both techniques involve combining multiple materials to create a final product, but they differ in their approach and applications.

Click to find more about what is the difference between insert molding and overmolding.

Insert Molding vs. Overmolding

Insert molding is a process where an insert or preformed component is placed into a mold cavity, and molten material is injected around it to form the final product. This technique allows for precise placement of inserts within the molded part, providing enhanced strength and functionality.

On the other hand, overmolding involves covering a base substrate with one or more additional layers of different materials. The base substrate can be made from metal, plastic, or any other suitable material. Overmolding provides improved aesthetics, comfort, grip, insulation properties, and protection against impact or vibration.

JVTECH: A Leader in Insert Molding

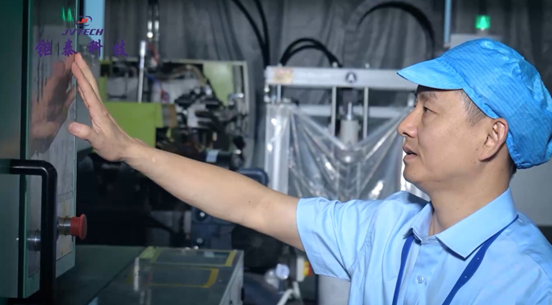

JVTECH has established itself as a leading provider of insert molding solutions. With state-of-the-art technology and expertise in design engineering and manufacturing processes, JVTECH offers high-quality products that meet customer requirements.

The company’s extensive experience enables them to optimize designs for efficient production while ensuring superior performance characteristics of insert-molded parts. By utilizing advanced machinery and quality control measures throughout the manufacturing process, JVTECH consistently delivers reliable products to its customers.

The Overmolding Design Guide by JVTECH

To assist customers in achieving successful overmolded products,JVTECH has developed an informative overmolding design guide.The guide covers various aspects such as material selection considerations,draft angles,tolerances,and tooling recommendations.It also provides insights on designing for manufacturability and cost-effectiveness.

By following the guidelines outlined in JVTECH’s overmolding design guide, customers can ensure that their products are optimized for performance, functionality, and durability. The guide serves as a valuable resource for designers and engineers looking to incorporate overmolding into their manufacturing processes.

Conclusion

In summary, insert molding involves placing an insert or preformed component into a mold cavity before injecting molten material around it. Overmolding, on the other hand, covers a base substrate with additional layers of different materials. Both techniques offer unique advantages depending on the desired outcome of the final product.

JVTECH specializes in insert molding solutions and provides comprehensive support throughout the design and manufacturing process. Their overmolding design guide is an invaluable resource for those seeking to optimize their products through this technique. By understanding these differences and leveraging JVTECH’s expertise, manufacturers can achieve superior results in their production processes.