Understanding the Role of Belt Fasteners

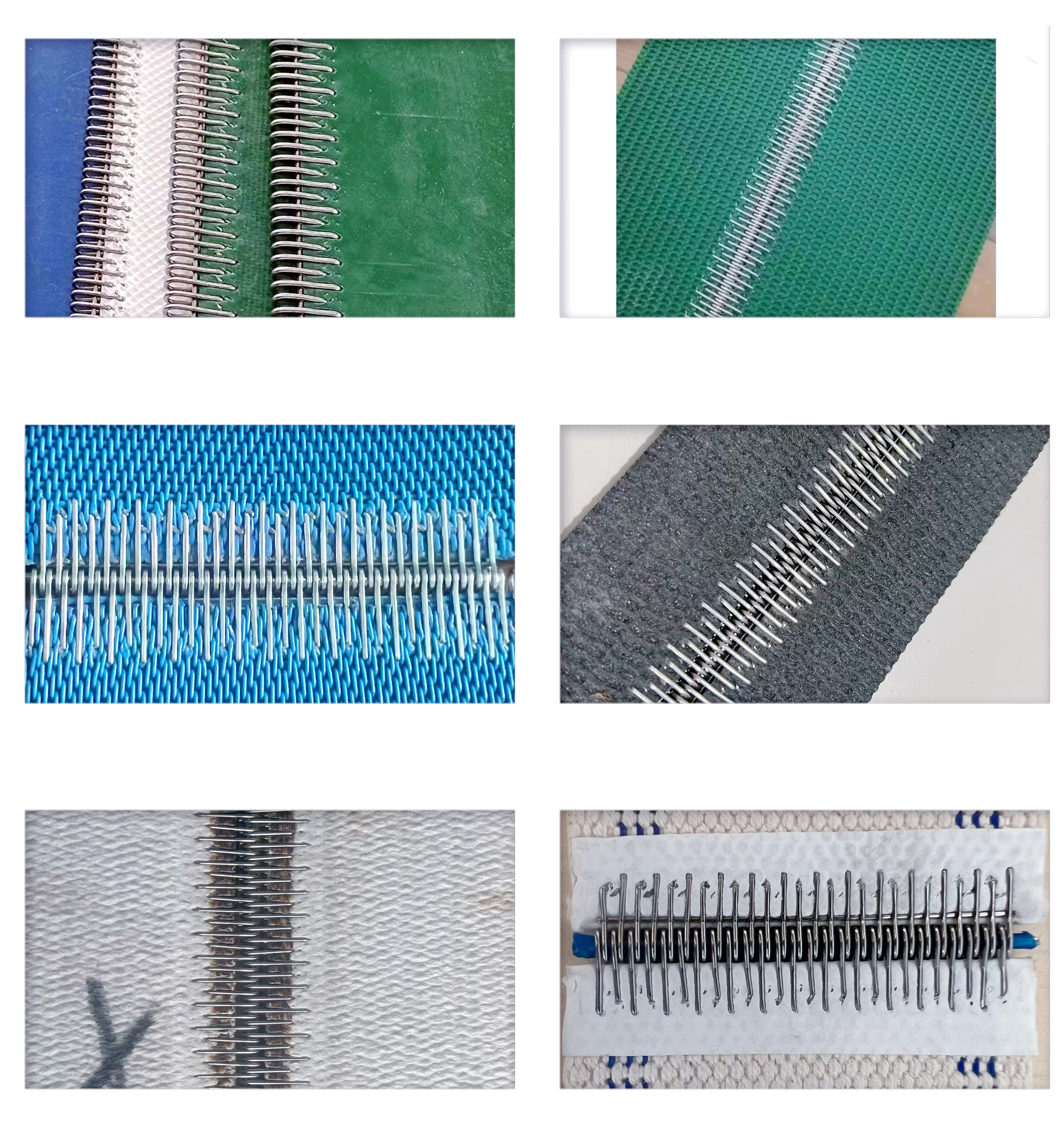

Belt fasteners are vital components in various industrial applications, ensuring the smooth operation of conveyor systems and machinery. The criticality of these fasteners lies in their ability to secure belts efficiently while maintaining optimal performance. As a belt fasteners manufacturer, businesses must focus on producing durable, reliable products that stand the test of time and considerable wear. High-quality fasteners provide stability and longevity, reducing downtime and maintenance costs. For industries that depend on conveyor belts, such as manufacturing and logistics, understanding the quality and specification of belt fasteners is paramount. Manufacturers who prioritize these aspects will find themselves better positioned in the market, attracting clients seeking reliable solutions. Furthermore, considering the technological advancements in manufacturing processes, such as precision engineering or innovative materials, can greatly enhance product offerings and ensure competitive advantages.

Why Choose a Reliable Belt Fastener Supplier

When selecting a belt fastener supplier, businesses should consider several key factors that contribute to reliability and performance. Quality assurance processes, a diverse product range, and customer service excellence are crucial. A supplier that adheres to rigorous testing standards can provide assurance that their fasteners meet industry expectations and regulations. Additionally, a knowledgeable customer service team can address inquiries efficiently, providing timely support when issues arise. For instance, a supplier with a wide variety of fasteners can cater to unique needs across different applications, whether it’s for heavy-duty environments or lighter tasks. It is also advantageous for businesses to seek suppliers with a proven track record. Testimonials and case studies can offer insight into a supplier’s reliability and performance, confirming their capability in meeting diverse industry needs. This proactive approach not only minimizes the risk of product failure but also fosters long-term partnerships that benefit both parties.

The Importance of Conveyor Belt Fasteners in Industry

For many sectors that rely on automated processes, the role of a conveyor belt fasteners manufacturer cannot be overstated. These fasteners are essential in maintaining seamless operations on assembly lines, ensuring that products are moved without interruption. Without robust fastening solutions, the risk of belt slippage or breakage increases, which can lead to costly downtimes. Manufacturers must adopt stringent quality controls and innovative designs to create effective fastening solutions that can withstand extensive operational stress. For instance, some manufacturers integrate advanced materials, such as corrosion-resistant alloys, to enhance the durability of their fasteners. By focusing on technological advancements, manufacturers can ensure that their products fully meet the specific demands of various industries. Additionally, ongoing research and development are essential to adapt to the evolving market needs, allowing manufacturers to offer innovative solutions tailored precisely to client requirements.

Conclusion: Choosing the Right Manufacturer for Your Needs

In summary, navigating the world of belt fasteners and their manufacturing calls for a thorough understanding of the product’s significance and quality. Reliable suppliers and manufacturers provide the assurance of durability and performance that industries depend on. Among the leading names in this domain is Intake, renowned for its supply advantages and commitment to quality. Choosing Intake as your manufacturer means benefitting from a wide range of high-quality fasteners crafted using the latest technologies, ensuring your operations run smoothly and efficiently. With a focus on customer satisfaction and technical expertise, Intake stands out as a trustworthy partner, ready to meet your unique fastening needs.